Temperature-Controlled Packaging Solutions Market Growth Drivers, Trends, Key Players and Regional Insights by 2035

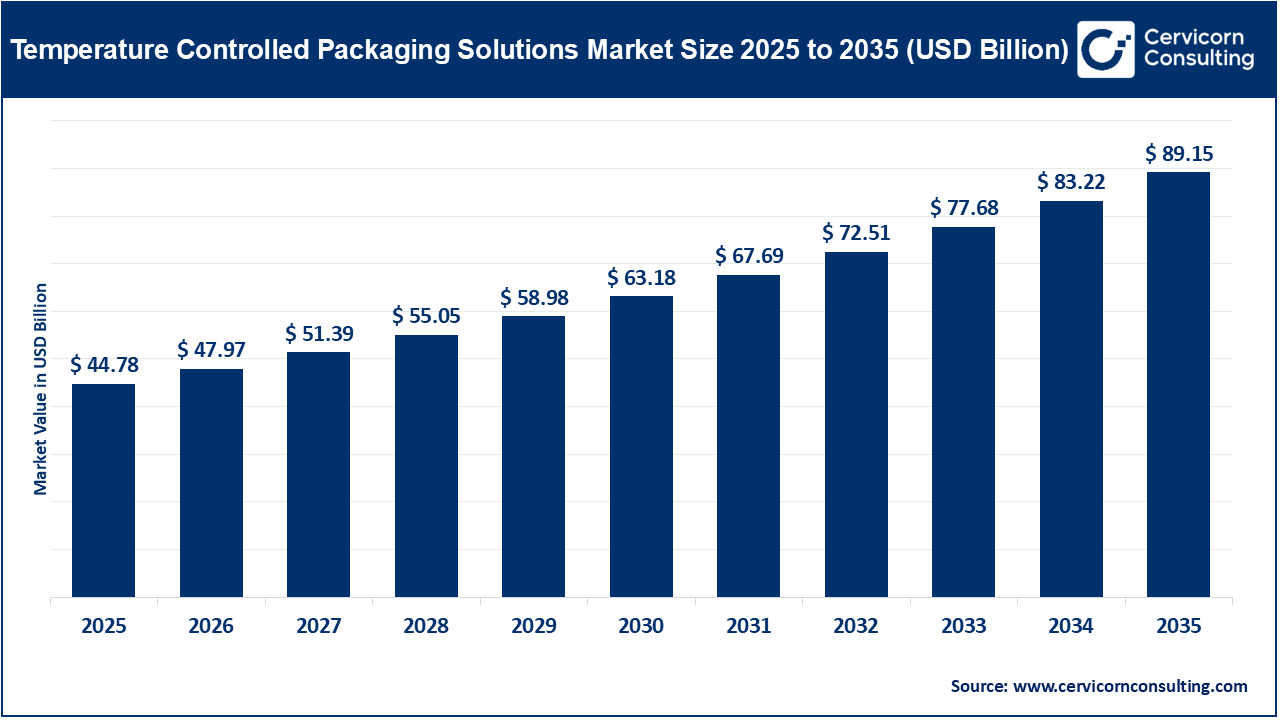

Temperature-Controlled Packaging Solutions Market Size

The global temperature-controlled packaging solutions market size was worth USD 44.78 billion in 2025 and is anticipated to expand to around USD 89.15 billion by 2035, registering a compound annual growth rate (CAGR) of 7.2% from 2026 to 2035.

What Is the Temperature-Controlled Packaging Solutions Market?

The temperature-controlled packaging solutions market refers to the global industry focused on designing, manufacturing, and deploying packaging systems that maintain a defined temperature range for sensitive products throughout storage, transportation, and distribution. These solutions are critical for goods that are vulnerable to temperature fluctuations, including pharmaceuticals, vaccines, biologics, fresh food, frozen products, specialty chemicals, and laboratory specimens.

Temperature-controlled packaging solutions can broadly be categorized into passive and active systems. Passive solutions rely on insulation materials and phase-change materials (PCMs) such as gel packs, dry ice, or eutectic plates to stabilize temperature without an external power source. Active solutions, by contrast, use powered refrigeration or heating systems that continuously regulate internal conditions. Together, these technologies form the backbone of cold chain logistics, enabling safe and efficient movement of temperature-sensitive goods across complex global supply networks.

As globalization intensifies and cross-border trade of sensitive products grows, temperature-controlled packaging has evolved from a niche logistics component into a strategic necessity across healthcare, food, and biotechnology industries.

Why Is the Market Important?

Temperature-controlled packaging solutions play a foundational role in modern supply chains. Their importance spans multiple industries:

Healthcare & Pharmaceuticals

Many pharmaceutical products — particularly vaccines, biologics, cell therapies, and insulin — are highly temperature sensitive. Even minor deviations can degrade efficacy, compromise patient safety, and result in costly product losses. Reliable temperature-controlled packaging ensures compliance with regulatory standards and preserves therapeutic integrity from manufacturing facilities to end users.

Food & Beverage Industry

Fresh, chilled, and frozen foods require strict temperature management to prevent spoilage and extend shelf life. As global food trade and online grocery platforms expand, thermal packaging solutions help reduce waste, maintain quality, and support long-distance distribution.

Economic & Environmental Impact

Temperature deviations lead to product spoilage, waste, recalls, and financial losses. Additionally, wasted pharmaceuticals and food products contribute to environmental burdens. Effective packaging solutions reduce waste, improve efficiency, and support sustainability objectives.

Global Trade & Logistics

With products crossing multiple climatic zones and transportation stages, temperature-controlled packaging ensures stability despite external environmental variability. This capability is increasingly vital for international commerce.

Get a Free Sample: https://www.cervicornconsulting.com/sample/2897

Growth Factors in the Temperature-Controlled Packaging Solutions Market

The temperature-controlled packaging solutions market is expanding rapidly due to a combination of technological, economic, and regulatory factors. Growth is largely driven by the accelerating biopharmaceutical sector, where biologics, gene therapies, and vaccines require precise thermal protection. The surge in global vaccine distribution programs has significantly increased demand for validated packaging systems capable of maintaining narrow temperature bands.

Simultaneously, the expansion of e-commerce — particularly for fresh food, meal kits, and perishable goods — has created new requirements for efficient, cost-effective thermal packaging solutions that perform reliably in last-mile delivery environments. Rising consumer expectations for product safety and quality further reinforce adoption.

Regulatory pressures also act as a powerful growth catalyst. Pharmaceutical and food safety agencies worldwide enforce strict guidelines governing temperature compliance, compelling manufacturers and logistics providers to invest in advanced packaging technologies. Non-compliance carries substantial financial and reputational risks.

Technological innovation represents another major growth factor. Advances in vacuum insulation panels (VIPs), phase-change materials (PCMs), smart sensors, IoT-enabled tracking systems, and AI-based monitoring tools are improving thermal performance, reliability, and visibility across the cold chain.

Sustainability considerations are increasingly influential. Companies are adopting recyclable and reusable packaging solutions to reduce environmental impact and long-term operational costs. Additionally, emerging economies are investing heavily in cold chain infrastructure, creating new regional demand for temperature-controlled packaging systems.

Together, these drivers are reshaping the market landscape and sustaining strong global growth momentum.

Key Company Profiles

Cold Chain Technologies

Specialization:

Cold Chain Technologies specializes in engineered thermal packaging solutions designed to protect temperature-sensitive products across pharmaceutical, biotechnology, and food supply chains.

Key Focus Areas:

- Passive thermal packaging systems

- Phase-change materials

- Temperature monitoring and data loggers

- Custom cold chain engineering

Notable Features:

The company is recognized for delivering high-performance insulated containers and tailored packaging designs that meet strict regulatory compliance requirements. It emphasizes reliability, durability, and temperature stability.

2024 Revenue:

Estimated in the mid-tens of millions USD range, reflecting steady expansion driven by pharmaceutical logistics demand.

Market Share:

Positioned as a strong mid-tier player with growing influence in life sciences packaging.

Global Presence:

Operations span North America, Europe, and Asia-Pacific, with increasing penetration in emerging markets.

Sonoco ThermoSafe

Specialization:

Sonoco ThermoSafe provides comprehensive temperature-controlled packaging solutions, including both passive and active systems.

Key Focus Areas:

- Insulated shipping containers

- Reusable thermal systems

- Sustainable packaging solutions

- Pharmaceutical logistics solutions

Notable Features:

The company is known for innovation in eco-friendly packaging and scalable cold chain solutions. Its offerings support pharmaceutical, biotech, and medical device industries.

2024 Revenue:

As part of Sonoco Products Company, revenue contribution is significant within the protective packaging segment.

Market Share:

Maintains a notable global share, supported by strong brand recognition and diversified product portfolio.

Global Presence:

Extensive international operations across North America, Europe, Latin America, and Asia-Pacific.

Tempack

Specialization:

Tempack focuses on lightweight and reusable temperature-controlled packaging solutions.

Key Focus Areas:

- Thermal boxes and containers

- Cold chain packaging for pharmaceuticals

- Food logistics solutions

Notable Features:

Tempack emphasizes efficiency, modularity, and reduced environmental footprint. Its solutions are designed for flexibility and cost effectiveness.

2024 Revenue:

Operates within the Tier-2 market segment, with steady growth across European markets.

Market Share:

Emerging regional competitor with expanding market visibility.

Global Presence:

Primarily Europe, with gradual expansion into adjacent markets.

Asiacooler

Specialization:

Asiacooler provides regionally optimized temperature-controlled packaging solutions tailored to Asia-Pacific logistics environments.

Key Focus Areas:

- Insulated cooler systems

- Packaging for food exports

- Pharmaceutical cold chain solutions

Notable Features:

Solutions designed to perform under diverse climatic conditions typical of Asian markets. The company often offers cost-efficient and customizable configurations.

2024 Revenue:

Represents a smaller regional player benefiting from rising cold chain investments.

Market Share:

Growing presence within Asia-Pacific markets.

Global Presence:

Strong regional footprint across Asia and Southeast Asia.

va-Q-tec AG

Specialization:

va-Q-tec AG is a technology leader in high-performance thermal insulation solutions utilizing vacuum insulation panels (VIPs).

Key Focus Areas:

- VIP-based containers

- Phase-change materials

- Reusable packaging systems

- Thermal logistics services

Notable Features:

Known for exceptional thermal stability and extended hold times. The company integrates advanced insulation with monitoring technologies.

2024 Revenue:

Reflects strong participation in premium temperature-controlled logistics and packaging segments.

Market Share:

Recognized as a key innovator with influence in high-performance packaging solutions.

Global Presence:

Broad operations across Europe, North America, and Asia-Pacific.

Sofrigam

Specialization:

Sofrigam specializes in validated temperature-controlled packaging systems, particularly for pharmaceutical and clinical trial logistics.

Key Focus Areas:

- Thermal shippers

- Phase-change solutions

- Compliance-oriented packaging

Notable Features:

Strong emphasis on regulatory compliance, validation, and secure transport for sensitive healthcare products.

2024 Revenue:

Operates within Tier-2 segment with steady growth momentum.

Market Share:

Notable presence in European cold chain packaging.

Global Presence:

Primarily Europe with expanding global partnerships.

Leading Trends and Their Impact

1. Dominance of Passive Packaging Solutions

Passive systems continue to lead due to cost efficiency, ease of deployment, and scalability. Innovations in insulation materials and PCMs have significantly enhanced performance.

Impact:

Broader accessibility and adoption across pharmaceutical and food logistics.

2. Integration of Smart Monitoring Technologies

IoT sensors, RFID tracking, and data loggers are becoming standard features.

Impact:

Improved cold chain visibility, reduced product losses, and enhanced compliance.

3. Sustainability & Circular Packaging Models

Recyclable and reusable packaging solutions are gaining traction.

Impact:

Reduced waste, lower lifecycle costs, and stronger alignment with ESG goals.

4. Growth of E-Commerce Cold Chain Logistics

Online grocery and direct-to-consumer pharmaceutical delivery are reshaping packaging requirements.

Impact:

Demand for lightweight, durable, and efficient last-mile solutions.

5. Expansion of Biopharmaceutical Logistics

Biologics and gene therapies require highly reliable temperature control.

Impact:

Acceleration of advanced packaging innovation and premium solution demand.

Successful Examples Around the World

Temperature-controlled packaging solutions have proven critical in several global contexts:

- Global Vaccine Distribution: Ensuring thermal integrity for vaccines across continents.

- International Food Exports: Preserving freshness of seafood, dairy, and produce.

- Clinical Trial Logistics: Maintaining stability of investigational drugs.

- Meal Kit & Grocery Delivery: Supporting last-mile thermal performance.

These examples illustrate how packaging innovation directly enables safe, scalable global trade.

Global Regional Analysis

North America

North America remains a dominant market driven by advanced cold chain infrastructure, strong pharmaceutical sector, and strict regulatory frameworks.

Government Influence:

Stringent temperature compliance regulations drive continuous innovation.

Europe

Europe emphasizes sustainability, compliance, and high-performance packaging.

Government Influence:

Environmental regulations encourage recyclable and reusable packaging systems.

Asia-Pacific

Asia-Pacific represents the fastest-growing region.

Growth Drivers:

- Expanding pharmaceutical manufacturing

- Rising food exports

- Cold chain infrastructure investments

Government Influence:

Policies supporting cold chain modernization and healthcare logistics.

Latin America

Growing demand supported by agricultural exports and healthcare improvements.

Government Influence:

Investment in logistics and food preservation systems.

Middle East & Africa

Emerging growth supported by healthcare expansion and infrastructure development.

Government Influence:

Cold chain investment programs and pharmaceutical distribution initiatives.

To Get Detailed Overview, Contact Us: https://www.cervicornconsulting.com/contact-us

Read Report: Protein Market Revenue, Trends, and Strategic Insights by 2035