Steel Plate Market Revenue, Trends, and Strategic Insights by 2035

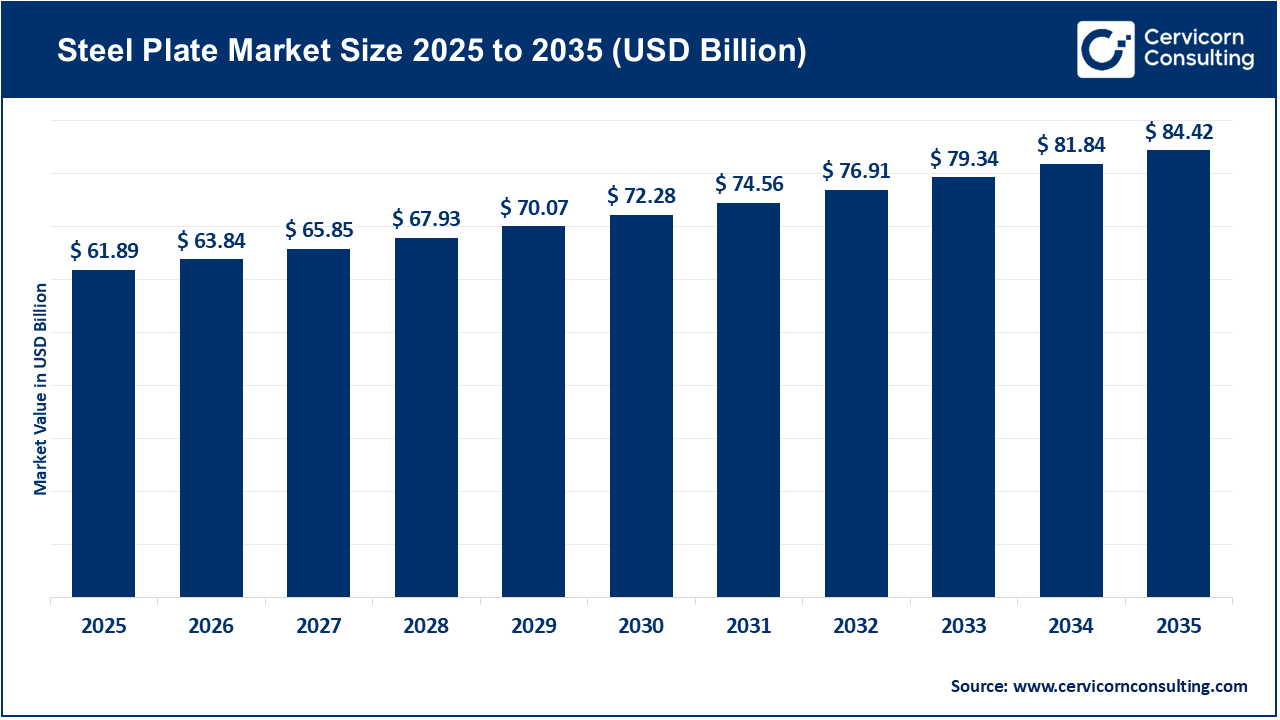

Steel Plate Market Size

The global steel plate market reached an estimated valuation of USD 61.89 billion in 2025 and is projected to grow substantially, attaining approximately USD 84.42 billion by 2035. This growth reflects a strong compound annual growth rate (CAGR) of around 3.3% throughout the forecast period.

What is the Steel Plate Market?

The steel plate market represents the global industry involved in the production, processing, distribution, and application of steel plates — flat steel products manufactured with thicknesses typically exceeding standard steel sheets. Steel plates are engineered to deliver superior mechanical strength, durability, resistance to extreme conditions, and load-bearing capacity. Unlike thinner steel sheets or coils, plates are used where structural integrity is critical.

Steel plates are produced through hot rolling or specialized metallurgical processes and are widely used across industries such as construction, shipbuilding, heavy machinery, automotive manufacturing, defense, energy, infrastructure, mining, pressure vessels, and industrial fabrication. Depending on composition and treatment, steel plates can be optimized for corrosion resistance, heat tolerance, abrasion resistance, or high tensile strength.

Because steel plates are fundamental to heavy-duty and high-performance engineering, the steel plate market plays a central role in global industrial development.

Get a Free Sample:https://www.cervicornconsulting.com/sample/2900

Steel Plate Market Growth Factors

The growth of the steel plate market is driven by a combination of structural economic forces and evolving industrial requirements. Large-scale global infrastructure investments continue to create strong demand for steel plates in bridges, buildings, rail networks, ports, and industrial facilities. Rapid urbanization, particularly in emerging economies, increases the need for durable construction materials capable of supporting high-density development.

Industrial expansion across manufacturing, mining, and machinery sectors fuels plate consumption for equipment, structural frameworks, and production systems. The automotive industry contributes through rising demand for advanced high-strength steel plates that improve vehicle safety and fuel efficiency. Energy sector developments — including oil & gas, pipelines, offshore platforms, and renewable energy installations — require specialized steel plate grades designed for harsh operating environments. Technological advancements in metallurgy, automation, and production efficiency enable manufacturers to produce higher-quality plates at competitive costs.

Additionally, rising defense budgets globally increase demand for heavy-duty steel plates used in armored vehicles, naval vessels, and protective infrastructure. Sustainability initiatives further accelerate innovation, encouraging investment in low-carbon steelmaking technologies. Together, these factors sustain long-term expansion and diversification of the steel plate market.

Why is the Steel Plate Market Important?

The steel plate market holds immense strategic and economic importance because steel plates underpin many of the world’s most critical industries. In construction and infrastructure, steel plates provide the structural backbone for bridges, high-rise buildings, industrial plants, and transport networks. Their strength and reliability make them indispensable for projects requiring long-term durability.

In manufacturing and heavy industry, steel plates enable the production of machinery, equipment, storage tanks, and pressure vessels. In shipbuilding and marine engineering, plates ensure hull strength, safety, and resilience against harsh oceanic conditions. In energy systems, steel plates support pipelines, wind turbines, power plants, and offshore platforms.

Steel plates are also vital to national security, used extensively in defense applications such as armored vehicles and naval vessels. Their widespread usage across foundational sectors makes the steel plate market a critical driver of industrialization, modernization, and economic development.

Major Companies Shaping the Steel Plate Market

China Baowu Group

China Baowu Group is the world’s largest steel producer and a dominant force in the steel plate segment. Formed through major mergers and strategic consolidation, the company operates a vertically integrated steelmaking ecosystem.

Specialization:

Integrated steel production, advanced steel plates, automotive steels, and structural materials.

Key Focus Areas:

Green steel technologies, smart manufacturing, high-strength plate innovation, and capacity expansion.

Notable Features:

China Baowu is known for its scale, operational efficiency, and leadership in low-carbon steelmaking initiatives. The company invests heavily in digitalization and sustainability-driven manufacturing processes.

2024 Revenue:

Approximately USD 130+ billion (company-wide).

Market Share:

Among the highest global steel production volumes, contributing significantly to flat steel and plate supply.

Global Presence:

Extensive operations across Asia, Europe, Africa, and the Americas through subsidiaries, exports, and partnerships.

ArcelorMittal

ArcelorMittal remains one of the most influential global steelmakers, with strong capabilities in steel plate manufacturing for construction, automotive, and industrial sectors.

Specialization:

Flat steel products, high-performance steel plates, coated steels, and mining-integrated operations.

Key Focus Areas:

Decarbonization, advanced material solutions, operational optimization, and supply chain efficiency.

Notable Features:

The company leads innovation in sustainable steel production, including hydrogen-based steelmaking and emissions-reduction technologies.

2024 Revenue:

Approximately USD 65–70 billion.

Market Share:

Consistently ranks among the world’s top steel producers.

Global Presence:

Operations in over 60 countries, spanning Europe, North America, South America, Asia, and Africa.

Ansteel Group

Ansteel Group is one of China’s major state-owned steel enterprises with strong production capabilities in heavy plates and structural steels.

Specialization:

Structural steel plates, heavy plates, hot-rolled steel products.

Key Focus Areas:

Industrial modernization, product diversification, efficiency improvements, and specialty plate production.

Notable Features:

Ansteel plays a major role in infrastructure-related steel supply and continues expanding its high-value steel product portfolio.

2024 Revenue:

Estimated USD 14–16 billion.

Market Share:

Strong domestic market share with increasing international exports.

Global Presence:

Primarily Asia-focused with expanding global trade networks.

Nippon Steel Corporation

Nippon Steel Corporation is globally recognized for producing technologically advanced and high-performance steel plates.

Specialization:

High-strength steel plates, specialty steels, automotive-grade materials.

Key Focus Areas:

Advanced metallurgy, lightweighting solutions, sustainable steelmaking technologies.

Notable Features:

The company is known for deep R&D expertise, enabling production of high-tensile and specialty steel plates used in demanding applications.

2024 Revenue:

Approximately USD 60+ billion.

Market Share:

Among the top global steel producers with strong influence in specialty plate segments.

Global Presence:

Strong footprint across Japan, ASEAN countries, Europe, and North America.

HBIS Group

HBIS Group is one of China’s largest steelmakers and a significant supplier of flat steel and steel plates.

Specialization:

Flat steel products, heavy plates, industrial steel materials.

Key Focus Areas:

Smart manufacturing, green steel production, international expansion.

Notable Features:

HBIS is recognized for its modernization initiatives and emphasis on environmentally responsible steel production.

2024 Revenue:

Estimated USD 55–60 billion.

Market Share:

Major contributor to China’s steel output.

Global Presence:

Exports to more than 80 countries, with strong presence in emerging markets.

Leading Trends in the Steel Plate Market and Their Impact

1. Rising Demand for High-Strength Steel Plates

Industries increasingly require steel plates with enhanced tensile strength and reduced weight. Automotive manufacturers, heavy machinery producers, and infrastructure developers benefit from materials that deliver superior strength-to-weight ratios.

Impact:

Higher value-added product segments, greater R&D investment, and premium pricing opportunities.

2. Technological Advancements in Manufacturing

Automation, AI-driven quality control, precision rolling, and digitalized production systems are transforming steel plate manufacturing.

Impact:

Improved product consistency, lower defect rates, cost efficiencies, and enhanced competitiveness.

3. Sustainability and Low-Carbon Steel Production

Environmental regulations and ESG commitments are reshaping steelmaking practices. Producers are investing in electric arc furnaces, hydrogen-based reduction, and energy-efficient processes.

Impact:

Shift in capital investments, emergence of green steel premiums, and evolving supply chain preferences.

4. Growth in Renewable Energy Infrastructure

Steel plates play a crucial role in wind turbines, offshore platforms, solar structures, and energy storage systems.

Impact:

Expansion of specialized steel grades and long-term stable demand.

5. Diversification of End-Use Applications

Steel plates are now widely used beyond traditional heavy industry, including advanced manufacturing, mobility solutions, and defense innovation.

Impact:

Market resilience and reduced dependence on cyclical industries.

Successful Examples of Steel Plate Market Applications Worldwide

Offshore Wind Energy Projects

Offshore wind farms require massive steel plates for turbine foundations, support structures, and platforms. Countries investing heavily in renewable energy have significantly stimulated plate demand.

Mega Infrastructure Developments

Large-scale bridge construction, railway expansions, and urban development projects worldwide rely on steel plates for structural stability.

Shipbuilding and Marine Engineering

Major shipbuilding nations continue to drive steel plate consumption for cargo vessels, naval ships, and offshore assets.

Defense Modernization Programs

Armored vehicles, naval vessels, and military infrastructure require specialized high-strength steel plates.

Global Regional Analysis

Asia-Pacific

Asia-Pacific dominates the steel plate market due to rapid urbanization, industrialization, and infrastructure investment. China, India, Japan, and South Korea lead production and consumption.

Government Initiatives & Policies

Governments across the region promote domestic steel production, capacity expansion, and industrial modernization. Infrastructure development programs significantly influence steel demand. Environmental regulations also drive investments in cleaner production technologies.

North America

North America exhibits stable demand supported by construction, energy, and manufacturing sectors.

Government Influence

Trade policies, domestic sourcing preferences, and sustainability regulations shape production and supply chains. Investment in recycled steel production continues to rise.

Europe

Europe emphasizes sustainability and technological innovation.

Government Initiatives

Strict emissions regulations and decarbonization frameworks influence steel production strategies. Investments in green steel technologies are particularly strong.

Middle East & Africa

This region shows growing demand driven by infrastructure expansion and industrial diversification.

Government Initiatives

Economic diversification strategies and industrial investment programs support steel consumption.

Latin America

Latin America experiences moderate growth linked to infrastructure and resource-driven industries.

Government Influence

Investment incentives and trade policies influence regional steel production dynamics.

To Get Detailed Overview, Contact Us: https://www.cervicornconsulting.com/contact-us

Read Report: AI in Clinical Workflow Market Revenue, Trends, and Strategic Insights by 2035