Air Compressor Market Growth Drivers, Trends, Key Players and Regional Insights by 2035

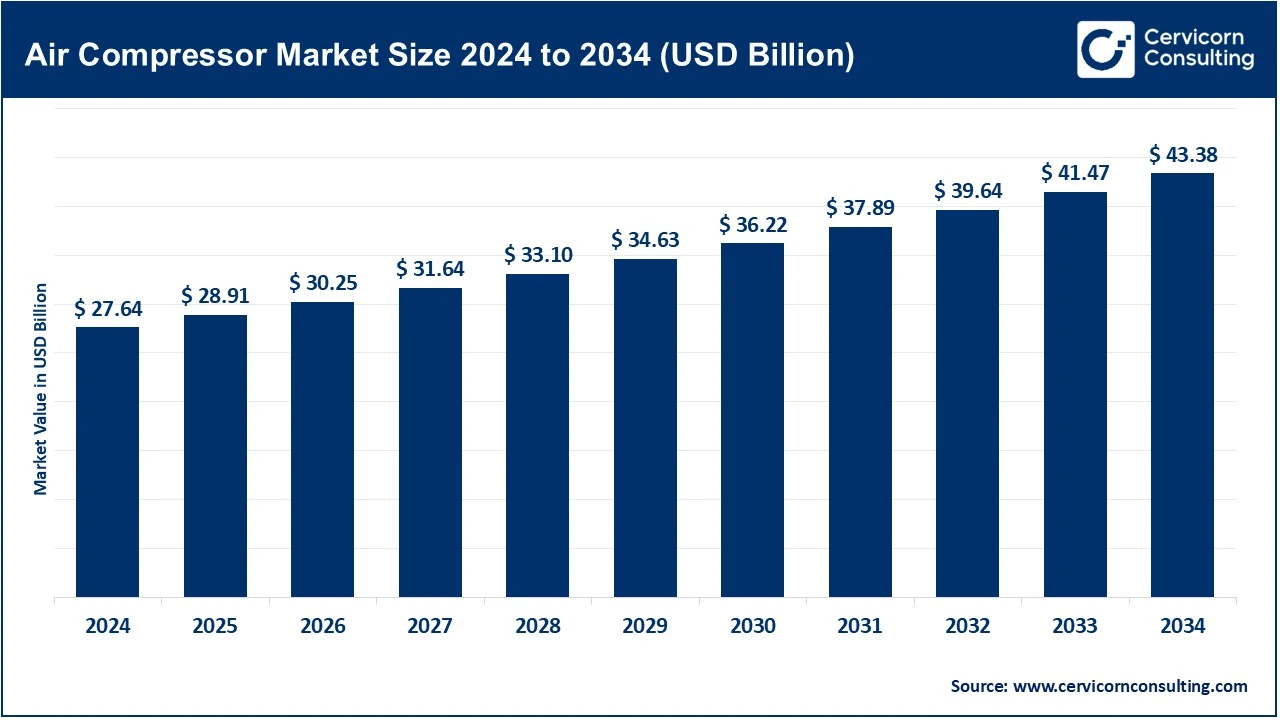

Air Compressor Market Size

The global air compressor market size was worth USD 27.64 billion in 2025 and is anticipated to expand to around USD 43.38 billion by 2035, registering a compound annual growth rate (CAGR) of 4.6% from 2026 to 2035.

What Is the Air Compressor Market?

The air compressor market refers to the global industry involved in the design, manufacturing, distribution, and servicing of air compressors and related equipment. This market includes a wide range of compressor types such as reciprocating (piston), rotary screw, centrifugal, and scroll compressors, along with oil-filled and oil-free variants tailored to specific applications.

Air compressors are classified based on mobility (stationary or portable), pressure capacity, power source, and end-use sector. They are used across diverse industries including manufacturing, automotive, food and beverage, pharmaceuticals, electronics, oil and gas, mining, healthcare, and construction. As of 2024, the market is valued in the multi-billion-dollar range and is projected to witness sustained growth through the next decade due to expanding industrial footprints and technological modernization.

Get a Free Sample: https://www.cervicornconsulting.com/sample/2849

Why Is the Air Compressor Market Important?

Compressed air is often referred to as the “fourth utility”, alongside electricity, water, and natural gas. Its importance lies in its versatility, safety, and efficiency in powering industrial processes. Unlike electrical systems, compressed air can be safely used in hazardous environments such as chemical plants, refineries, and mines without the risk of sparks or electrical failures.

In manufacturing, air compressors enable automation, operate pneumatic tools, and maintain precision in production processes. In healthcare, clean and oil-free compressed air is essential for operating medical devices and ensuring sterile environments. The food and beverage industry relies on compressed air for packaging, bottling, and quality control, while the electronics and semiconductor sectors demand ultra-clean air for precision fabrication.

Because compressed air directly impacts productivity, energy efficiency, and operational continuity, the air compressor market is a critical enabler of industrial growth and economic development worldwide.

Air Compressor Market Growth Factors

The growth of the air compressor market is driven by a combination of industrial expansion, technological innovation, and regulatory pressures. Rapid industrialization in emerging economies, particularly in Asia Pacific, has significantly increased demand for compressed air systems across manufacturing and infrastructure sectors. Automation trends in automotive, electronics, and heavy industries further amplify this demand, as pneumatic systems remain integral to production efficiency.

Energy efficiency regulations and rising electricity costs are compelling industries to adopt advanced compressor technologies such as variable speed drives and energy-optimized systems. Additionally, the growing emphasis on sustainability has accelerated the shift toward oil-free and low-emission compressors, particularly in environmentally regulated regions. The integration of digital monitoring, predictive maintenance, and smart control systems has also enhanced operational reliability and reduced lifecycle costs, making modern compressors more attractive investments for businesses.

Company Profiles

Atlas Copco AB

Specialization:

Atlas Copco AB is a global leader in compressed air and gas solutions, known for its extensive portfolio of industrial compressors, vacuum systems, and air treatment products. The company focuses heavily on innovation, energy efficiency, and digital integration.

Key Focus Areas:

- Industrial and oil-free air compressors

- Energy-efficient and variable speed drive systems

- Smart, connected compressor solutions

Notable Features:

- Strong emphasis on sustainability and lifecycle efficiency

- Advanced digital platforms for monitoring and maintenance

- Comprehensive global service network

2024 Revenue & Market Share:

Atlas Copco commands a leading share of the global air compressor market, with a substantial portion of its total revenue generated through compressor systems and aftermarket services.

Global Presence:

Operations in more than 180 countries with manufacturing, sales, and service facilities across Europe, Asia, the Americas, and Africa.

Bauer Compressors Inc.

Specialization:

Bauer Compressors Inc. specializes in high-pressure compressors and gas management systems. It is particularly well-known for breathing air compressors used in medical, firefighting, diving, and industrial safety applications.

Key Focus Areas:

- High-pressure air and gas compressors

- Breathing air purification systems

- Industrial and safety-critical applications

Notable Features:

- High reliability in extreme and safety-sensitive environments

- Strong focus on air purity and compliance standards

2024 Revenue & Market Share:

Bauer Compressors operates as part of a globally recognized group with strong revenues derived from niche, high-value compressor segments.

Global Presence:

Extensive international dealer and service network spanning Europe, North America, Asia, and Oceania.

Doosan Corporation

Specialization:

Doosan Corporation manufactures portable and industrial air compressors primarily for construction, mining, and infrastructure projects. Its compressors are designed for durability and high performance in demanding environments.

Key Focus Areas:

- Portable diesel and electric air compressors

- Construction and heavy-industry applications

Notable Features:

- Rugged design suitable for harsh operating conditions

- Strong alignment with infrastructure and energy projects

2024 Revenue & Market Share:

Air compressors form a strategic part of Doosan’s industrial equipment portfolio, contributing to its presence in global construction and infrastructure markets.

Global Presence:

Strong footprint in Asia, North America, Europe, and emerging markets through distributors and regional operations.

ELGi Equipments Limited

Specialization:

ELGi Equipments Limited is a leading Indian manufacturer of air compressors, offering a broad range of stationary, portable, and oil-free compressor solutions.

Key Focus Areas:

- Oil-free and energy-efficient compressors

- Industrial and automotive applications

- Customized compressed air solutions

Notable Features:

- Strong focus on engineering innovation and localized solutions

- Competitive pricing with global quality standards

2024 Revenue & Market Share:

ELGi has recorded strong annual revenues, driven by domestic demand and expanding international sales.

Global Presence:

Active in over 120 countries, with a particularly strong presence in Asia Pacific, the Middle East, and Africa.

Hitachi Ltd.

Specialization:

Hitachi Ltd. integrates air compressor solutions within its broader industrial systems and infrastructure portfolio, focusing on efficiency, automation, and digital transformation.

Key Focus Areas:

- Industrial air and gas systems

- Smart manufacturing and automation

- Energy-efficient industrial equipment

Notable Features:

- Advanced engineering and system integration capabilities

- Strong emphasis on digital and sustainable technologies

2024 Revenue & Market Share:

Air compressors contribute to Hitachi’s industrial systems revenues, supported by its global brand strength and technological expertise.

Global Presence:

Extensive operations across Asia, Europe, North America, and emerging markets.

Leading Trends and Their Impact

Smart and Connected Compressors

The integration of IoT sensors and digital control systems allows real-time performance monitoring, predictive maintenance, and operational optimization, reducing downtime and maintenance costs.

Energy Efficiency and Sustainability

Rising energy prices and environmental regulations are accelerating adoption of variable speed drive compressors, heat recovery systems, and low-emission designs that minimize energy consumption.

Oil-Free Compressor Demand

Industries requiring contamination-free environments—such as pharmaceuticals, food processing, and electronics—are increasingly adopting oil-free compressors to meet strict quality and safety standards.

Service-Based Business Models

Compressor-as-a-service, leasing, and rental models are gaining traction, enabling businesses to reduce capital expenditure while ensuring reliable compressed air supply.

Customization and Modular Designs

Manufacturers are offering modular, application-specific compressors that can be scaled and adapted to evolving operational needs.

Successful Examples of Air Compressor Market Adoption Worldwide

In semiconductor manufacturing hubs, advanced oil-free compressors supply ultra-clean air required for microchip fabrication.

In automotive manufacturing, rotary screw compressors power robotic assembly lines and pneumatic tools across production facilities.

In energy and oil & gas projects, heavy-duty compressors support pipeline operations, gas processing, and refinery systems.

In healthcare facilities, medical-grade compressors ensure reliable and contamination-free air supply for critical applications.

Global Regional Analysis

Asia Pacific

Asia Pacific represents the largest and fastest-growing air compressor market, driven by industrialization, infrastructure development, and government-led manufacturing initiatives. Countries such as China, India, Japan, and South Korea dominate demand across automotive, electronics, and heavy industries.

North America

North America exhibits strong demand for energy-efficient and technologically advanced compressors, supported by automation trends and strict environmental regulations. The region focuses heavily on digitalization and operational efficiency.

Europe

Europe’s market is shaped by sustainability goals and stringent energy regulations. Industries prioritize low-emission, high-efficiency compressors to comply with environmental standards and reduce carbon footprints.

Latin America

Growth in Latin America is driven by construction, mining, and industrial modernization projects, with increasing adoption of portable and industrial compressor systems.

Middle East & Africa

This region benefits from large-scale infrastructure and energy projects. Demand is driven by oil & gas operations, construction, and industrial diversification initiatives.

Government Initiatives and Policy Influence

Government policies play a critical role in shaping the air compressor market. Energy efficiency standards encourage adoption of advanced compressor technologies, while industrial development programs stimulate manufacturing activity and infrastructure growth. Incentives for sustainable and low-carbon technologies further support the transition toward energy-efficient and oil-free compressor systems across regions.

To Get Detailed Overview, Contact Us: https://www.cervicornconsulting.com/contact-us

Read Report: Fertility Market Growth Drivers, Trends, Key Players and Regional Insights by 2034