Food Processing Market Size

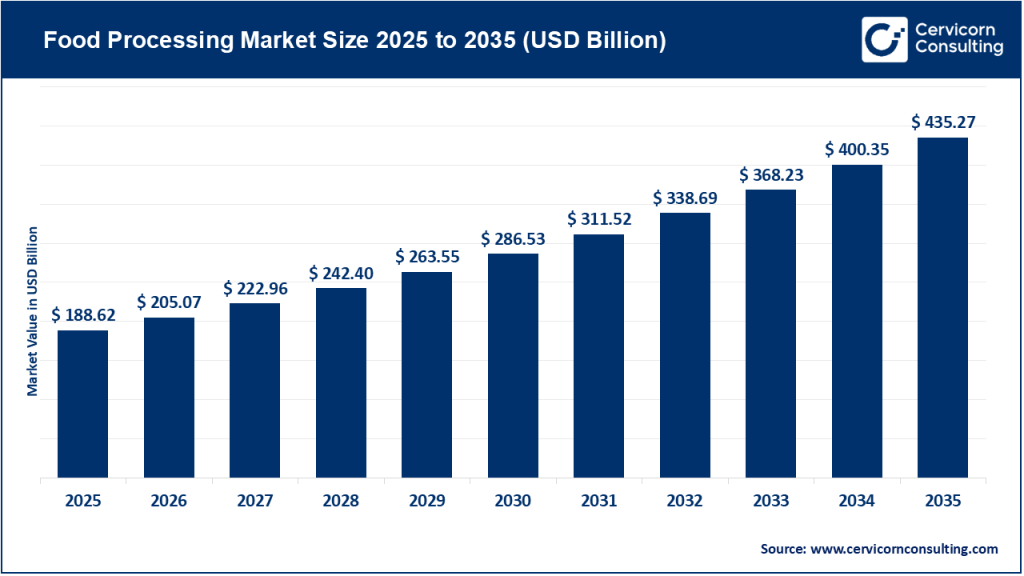

The global food processing market size was worth USD 188.62 billion in 2025 and is anticipated to expand to around USD 435.27 billion by 2035, registering a compound annual growth rate (CAGR) of 8.72% from 2026 to 2035.

What Is the Food Processing Market?

The food processing market encompasses all the activities, technologies, and systems involved in transforming raw agricultural products—such as grains, fruits and vegetables, meat, dairy, fish—into consumable, shelf-stable, value‑added food products. This includes a vast array of processes: cleaning, grading, sorting, pasteurization, canning, freezing, fermentation, cutting, forming, packaging, and more. On the equipment side, the market includes machinery (e.g., slicers, extruders, cookers), processing systems, automation and software (control systems, traceability), and services (maintenance, aftermarket support).

Growth Factors of the Food Processing Market

Several key drivers fuel the growth of the food processing market. Rapid urbanization and a rising global population are prompting higher demand for processed, convenient, ready-to-eat foods; changes in consumer lifestyles are increasing reliance on packaged and shelf-stable products. Technological innovation, including automation, robotics, IoT, and AI, is enhancing efficiency, reducing waste, and improving food safety. Stringent food safety standards and regulatory pressures push processors to modernize their operations. Meanwhile, sustainability trends—such as clean-label products, energy-efficient processing, and reduction of food waste—are encouraging investment in green processing technologies. Lastly, government support through incentives, investments in infrastructure, and supportive policies in emerging economies also underpins sector expansion.

Get a Free Sample: https://www.cervicornconsulting.com/food-processing-market

Why Is the Food Processing Market Important?

The food processing market is central to global food security, economic development, and consumer convenience. By converting raw agricultural outputs into value-added products, food processing extends shelf life, reduces post-harvest losses, and ensures food safety, thereby making food more accessible and affordable. Processed foods can be distributed across long distances, supporting global trade and supply chains. Economically, the food processing industry generates employment—from farming and procurement through to manufacturing, packaging, and logistics—and contributes significantly to GDP. Furthermore, innovation in processing supports improved nutrition (e.g., fortified foods), sustainability (reducing waste, more efficient resource use), and responds to consumer demand for convenience, traceability, and quality.

Top Companies in the Global Food Processing Market

Here, we look at several major players in the food processing equipment & systems market: Marel, BAADER Group, Bühler AG, The Middleby Corporation, and GEA Group AG.

1. Marel hf.

- Specialization: Marel is a leading global provider of advanced food processing equipment, systems, software, and services. They focus on multiple protein sectors: poultry, meat, fish, and also plant-based and pet feed.

- Key Focus Areas: Their solutions cover full-line processing: primary processing (live animal handling, chilling), secondary processing (cut-up, filleting), and further processing (marinating, forming, coating). They also provide software, digital tools, robotics, vision systems, and services.

- Notable Features: Marel invests heavily in innovation and sustainability: their new products are assessed for resource efficiency, waste reduction, and circularity. They use data-driven solutions, AI, vision systems for grading and automation.

- 2024 / Recent Revenue: In 2023, Marel reported €1.7 billion in revenues. Their trailing twelve-month revenue as of Q3 2024 was around €1.66 billion.

- Market Share & Global Presence: Marel operates in over 30 countries and serves customers in more than 140 countries globally. Their business is diversified: in Q1 2024, ~52.8% of their revenues came from poultry, ~24.7% from meat, ~9.6% from fish, and ~11% from plant/pet/feed.

2. BAADER Group

- Specialization: BAADER is known for food processing machinery, particularly in fish and seafood processing, but also in poultry and meat.

- Key Focus Areas: They provide equipment for sorting, cutting, portioning, grading, filleting, trimming, and portion packaging, especially tailored for seafood and fish processing.

- Notable Features: BAADER emphasizes high-yield processing, minimal waste, hygiene, and gentle handling (important in seafood). Their machines are modular and customizable, integrating automation and smart control.

- 2024 / Recent Revenue: Publicly available detailed 2024 revenue for BAADER Group is limited, but they are recognized as a significant specialist in the seafood processing equipment market.

- Market Share & Global Presence: BAADER has a strong presence in Europe and global seafood hubs, supplying major fish processors worldwide.

3. Bühler AG

- Specialization: Bühler is a Swiss technology company that supplies a broad portfolio of food processing technologies, especially for grains, cereals, plant-based proteins, chocolate, and more.

- Key Focus Areas: Their business spans grain milling, food extrusion, grinding, chocolate processing, and protein extraction. In recent years, they have also focused on plant-based protein markets.

- Notable Features: Bühler’s innovation centers develop fully integrated, sustainable solutions for protein isolation, fiber extraction, starch side streams, etc. They also help customers improve energy efficiency and reduce CO₂ emissions.

- 2024 Revenue: Bühler’s 2024 report notes business performance and orders, though total revenue for food processing vs. other areas isn’t split in a single number.

- Market Share & Global Presence: Bühler operates globally, with operations and sales across Europe, North America, Asia, Africa, and beyond. Their technology and R&D make them leaders in grains, proteins, and high-value foods.

4. The Middleby Corporation

- Specialization: Middleby is a U.S.-based company known for commercial kitchen equipment and industrial food processing machinery. Their product range includes ovens, mixers, fryers, coatings, and industrial food processing solutions.

- Key Focus Areas: They serve foodservice (restaurants, hotels), but also industrial food manufacturers. Their processing business covers frying, forming, baking, and thermal processing.

- Notable Features: Middleby’s equipment is widely used in large-scale operations, foodservice chains, and industrial food plants. Middleby is actively evaluating strategies to spin off its food processing business.

- 2024 Revenue: According to their 2024 annual report (post spin-merger), JBT Marel reported revenue of $1.72 billion.

- Market Share & Global Presence: Middleby and JBT Marel have a broad global footprint through JBT’s distribution and reach. Their processing equipment is used across continents in food-manufacturing facilities and foodservice industries.

5. GEA Group Aktiengesellschaft (AG)

- Specialization: GEA is a German multinational corporation designing process technology for the food, beverage, and pharmaceutical industries. They cover slicing, packaging, extrusion, bakery lines, pasta, snacks, meat, poultry, and vegan products.

- Key Focus Areas: Their Food & Healthcare Technologies division provides efficient production lines, processors for slicing & packaging, extruders, bakery systems, and lines for meat, seafood, and vegan products.

- Notable Features: GEA integrates sustainability in their systems, offering energy-efficient processing, carbon capture systems, emission control, and high-throughput lines with hygienic design.

- 2024 Revenue: GEA’s Food & Healthcare Technologies division revenue was €1,674 million.

- Market Share & Global Presence: GEA is globally recognized, serving multiple sectors and geographies, with strong operations in Europe, Asia, and the Americas.

Leading Trends and Their Impact

Several trends are shaping—and transforming—the global food processing market:

Automation, Industry 4.0 & Digitalization

- Adoption of automation, robotics, AI, and IoT is growing quickly. Smart systems enable real‑time monitoring, predictive maintenance, and data-driven quality control, reducing downtime and improving throughput. Digital traceability solutions strengthen food safety and supply chain transparency.

Sustainability & Resource Efficiency

- Pressure to reduce energy consumption, water usage, and food waste is pushing processors to adopt green processing technologies. Circular economy models are emerging, reusing by-products or extracting proteins, fibers, or starch from waste.

Clean Label, Plant-Based & Functional Foods

- Demand is rising for minimally processed foods, clean-label ingredients, and plant-based proteins. Processing technologies are refined to handle plant-based raw materials with better yield, texture, and nutrition. Functional foods require tailored process lines to preserve bioactives.

Cold‑Chain & Packaging Innovations

- Growth in frozen, ready-to-eat, and chilled foods demands advanced packaging, vacuum systems, and shelf-life–extending technologies. Sustainable, recyclable, or biodegradable packaging is increasingly important.

Regulatory Pressure & Food Safety

- Stringent food safety standards worldwide are pushing companies to adopt traceability systems, hygienic design, and advanced process control. Automation and software help achieve compliance cost-effectively.

Regionalization & Localization

- Local governments in key regions support food processing infrastructure (food parks, cold chain) to strengthen food security and reduce import dependence, encouraging local processing capacity.

Successful Examples from Around the World

Mega Food Parks in India

- India’s “Mega Food Park” scheme links farm → collection centers → primary processing → consumer markets, boosting value addition and reducing post-harvest waste.

Bühler’s Plant-Based Protein Facility

- Bühler opened a Protein Application Center to support extraction of proteins, fibers, and starch from pulses, demonstrating circular valorization.

Marel’s Global Reach in Seafood

- Marel’s processing lines for fish operate in more than 140 countries, using vision and robotics to improve yield and reduce waste in filleting and trimming.

GEA’s Energy‑Efficient Processing Lines

- GEA’s designs for bakery, extrusion, and meat processing focus on energy savings and hygienic design, enabling manufacturers to produce sustainably and efficiently.

Regional & Global Analysis: Markets, Policies, and Government Initiatives

Asia-Pacific

- Rapid urbanization, rising incomes, and changing lifestyles are driving processed food consumption.

- India invests in processing infrastructure through PLI schemes, mega food parks, cold chains, and agro-processing clusters.

- The middle-class population in China, India, and Southeast Asia fuels demand for convenient and packaged foods.

North America

- Mature market with high technology adoption, automation, and strong demand for clean-label and functional foods.

- Major adopter of smart processing equipment, robotics, and traceability systems.

Europe

- Market shaped by strict regulatory frameworks on food safety, sustainability, and environmental impact.

- Home to Bühler and GEA, Europe is a center for innovation in green processing and high-efficiency systems.

- Compliance with international standards is a key factor driving modernization.

Latin America & Middle East / Africa

- Latin America: improving processing capacity in meat, poultry, and fruits to integrate with global value chains.

- Middle East & Africa: urbanization, food security, and investments in cold chain and packaging reduce waste.

Government Initiatives & Policies

- India’s Ministry of Food Processing Industries supports infrastructure via Mega Food Parks, cold-chain projects, agro-clusters, and Operation Greens.

- Global food safety regulations encourage adoption of traceability systems and hygienic designs.

- Sustainability policies incentivize energy-efficient processing, waste reduction, and circular economy models.

To Get Detailed Overview, Contact Us: https://www.cervicornconsulting.com/contact-us

Read Report: Vehicle to Load (V2L) Market Revenue, Global Presence, and Strategic Insights by 2034