Distributed Control Systems Market Size

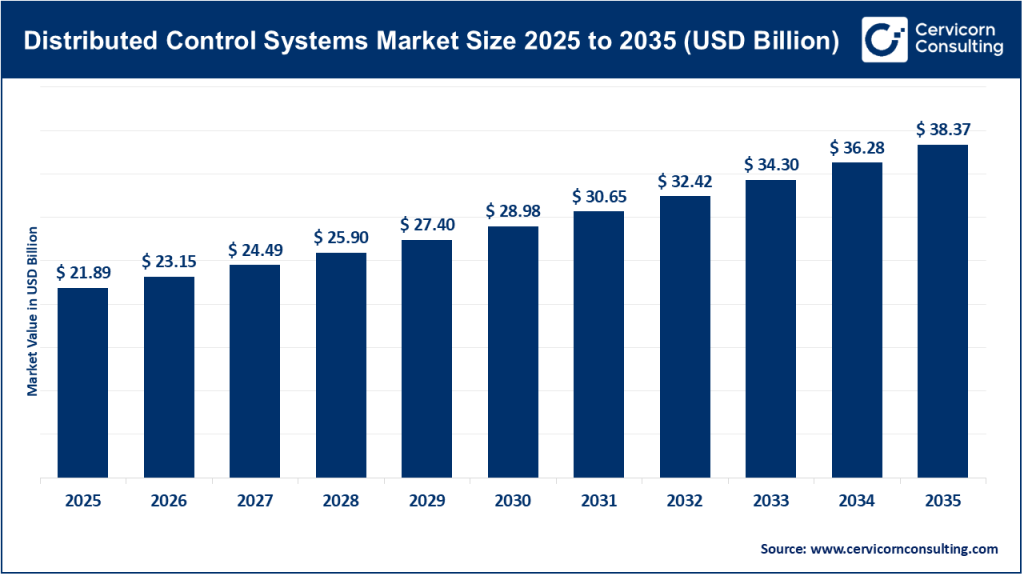

The global distributed control systems market size was worth USD 21.89 billion in 2025 and is anticipated to expand to around USD 38.37 billion by 2035, registering a compound annual growth rate (CAGR) of 5.8% from 2026 to 2035.

Distributed Control Systems Market Growth Factors

The growth of the distributed control systems market is driven by a combination of industrial expansion, increasing automation adoption, energy transition initiatives, and digitalization of manufacturing processes, with key factors including rising investments in power generation and renewable energy projects, modernization of legacy control systems across industrial plants, growing emphasis on operational efficiency and predictive maintenance, increasing safety and regulatory compliance requirements, labor shortages prompting automation, and government-backed initiatives promoting smart manufacturing, infrastructure development, and emission reduction, all of which collectively accelerate the adoption of advanced DCS solutions across global industries.

What Is the Distributed Control Systems Market?

The distributed control systems market encompasses the development, deployment, and servicing of hardware, software, and integrated solutions designed to automate, monitor, and control industrial processes in a distributed manner. DCS platforms typically include controllers, input/output modules, sensors, actuators, operator workstations, engineering tools, and communication networks that function cohesively to manage complex operations. Unlike programmable logic controller (PLC) systems that are often used for discrete manufacturing, DCS solutions are specifically designed for continuous and batch process industries where reliability, synchronization, and precision are paramount.

DCS architectures support large-scale operations involving thousands of control loops, making them essential for industries that require uninterrupted processes and real-time decision-making. The market also includes lifecycle services such as system integration, maintenance, upgrades, cybersecurity services, and training, which form a significant portion of vendor revenues and long-term customer relationships.

Get a Free Sample: https://www.cervicornconsulting.com/sample/2863

Why Is the Distributed Control Systems Market Important?

The importance of the distributed control systems market lies in its ability to ensure safe, efficient, and resilient industrial operations. In sectors such as oil & gas, chemicals, and power generation, operational failures can result in significant financial losses, safety risks, and environmental damage. DCS platforms provide deterministic control, redundancy, and fail-safe mechanisms that minimize operational disruptions and protect critical assets.

Beyond operational stability, DCS solutions play a strategic role in enabling digital transformation. Advanced analytics, real-time monitoring, and data integration allow organizations to transition from reactive maintenance to predictive and condition-based maintenance strategies. Additionally, DCS platforms support sustainability initiatives by optimizing energy consumption, reducing emissions, minimizing waste, and improving overall resource efficiency. As regulatory requirements around safety, quality, and environmental compliance become more stringent, the role of DCS in ensuring adherence to these standards continues to grow.

Key Companies in the Distributed Control Systems Market

Azbil Corporation

Company Overview:

Azbil Corporation is a prominent player in industrial automation and control systems, with a strong presence in process automation, building automation, and measurement technologies.

Specialization:

Distributed control systems, factory automation, advanced measurement instruments, and smart facility solutions.

Key Focus Areas:

Smart factories, IIoT-enabled process control, energy efficiency, and sustainable industrial operations.

Notable Features:

Azbil’s DCS platforms emphasize reliability, seamless integration with industrial IoT technologies, and advanced data analytics. The company focuses on user-centric design and real-time operational intelligence.

2024 Revenue:

Azbil reports strong overall automation revenue, with DCS contributing as part of its broader industrial automation portfolio.

Market Share:

Azbil holds a notable share in Asia-Pacific markets, particularly in Japan and surrounding regions.

Global Presence:

Headquartered in Japan, Azbil operates across Asia, North America, Europe, and other international markets.

HollySys Automation Technologies

Company Overview:

HollySys is a leading automation technology provider, particularly recognized for its distributed control systems and safety automation platforms.

Specialization:

Proprietary DCS platforms, safety instrumented systems, and intelligent manufacturing solutions.

Key Focus Areas:

Industrial intelligence, network security, high-reliability automation, and digital transformation.

Notable Features:

HollySys DCS solutions are known for integrated safety, scalable architecture, and adaptability across power, chemical, rail, and manufacturing industries.

2024 Revenue:

HollySys generates substantial revenue from automation systems and industrial software, with DCS representing a core segment.

Market Share:

The company holds a strong market position in China and continues to expand internationally.

Global Presence:

Based in China, HollySys serves customers across Asia and selected global markets.

Concept Systems

Company Overview:

Concept Systems operates as a specialized automation and control solutions provider, focusing on tailored industrial control implementations.

Specialization:

Custom distributed control systems, system integration, and industrial automation services.

Key Focus Areas:

Modular automation, scalable control architectures, and project-specific DCS solutions.

Notable Features:

Concept Systems is recognized for its flexible system designs and ability to integrate with multiple industrial platforms.

2024 Revenue:

Revenue is primarily project-based and regionally concentrated.

Market Share:

The company holds a smaller but niche market share compared to global automation leaders.

Global Presence:

Primarily regional operations with selective international projects.

ABB Ltd.

Company Overview:

ABB is one of the world’s largest industrial automation and technology companies, with a long-standing leadership position in distributed control systems.

Specialization:

Advanced DCS platforms, industrial automation, electrification, and digital solutions.

Key Focus Areas:

Energy, utilities, oil & gas, chemicals, metals, and manufacturing industries.

Notable Features:

ABB’s DCS offerings feature high reliability, advanced analytics, integrated safety systems, and scalable architectures designed for complex industrial environments.

2024 Revenue:

ABB’s automation business contributes significantly to its global revenue, with DCS platforms representing a major component.

Market Share:

ABB consistently ranks among the top global DCS vendors, historically holding one of the largest installed base shares.

Global Presence:

ABB operates in over 100 countries, serving customers across all major industrial regions.

Emerson Electric

Company Overview:

Emerson Electric is a global technology and engineering company with a strong footprint in automation solutions and industrial software.

Specialization:

Distributed control systems, process automation, instrumentation, and digital transformation technologies.

Key Focus Areas:

Oil & gas, power generation, chemicals, life sciences, water management, and manufacturing.

Notable Features:

Emerson’s DCS platforms emphasize modular design, digital twins, predictive diagnostics, and lifecycle management.

2024 Revenue:

Automation solutions form a substantial portion of Emerson’s annual revenue, with DCS as a core offering.

Market Share:

Emerson holds a leading share of global DCS installations and is widely recognized for its technological innovation.

Global Presence:

The company maintains extensive operations across North America, Europe, Asia-Pacific, the Middle East, and Latin America.

Leading Trends and Their Impact on the DCS Market

The distributed control systems market is undergoing rapid transformation driven by several key trends. The integration of IIoT and advanced analytics allows DCS platforms to process vast volumes of operational data in real time, improving visibility and decision-making. Cloud and edge computing are enabling hybrid architectures that combine centralized data analysis with localized control, enhancing scalability and flexibility.

Artificial intelligence and machine learning are increasingly embedded into DCS platforms to support predictive maintenance, anomaly detection, and process optimization. Cybersecurity has emerged as a critical focus area as DCS systems become more connected to enterprise networks and external platforms. Additionally, vendors are emphasizing modular and flexible system designs to cater to both large-scale industrial plants and smaller, distributed production facilities.

Successful Examples of Distributed Control Systems Around the World

Across the globe, distributed control systems have been successfully deployed in large-scale industrial projects. In oil refineries and petrochemical complexes, DCS platforms manage thousands of control loops to ensure safe and efficient continuous operations. Power generation facilities rely on DCS solutions to coordinate boiler, turbine, and grid interactions while maintaining high availability and efficiency.

Chemical manufacturing plants use DCS technology to maintain precise control over multi-stage reactions, ensuring consistent product quality and regulatory compliance. Water and wastewater treatment facilities have adopted DCS platforms to modernize operations, improve resource efficiency, and ensure uninterrupted service delivery to growing urban populations.

Global Regional Analysis and Government Initiatives Shaping the Market

Asia-Pacific

Asia-Pacific represents the largest and fastest-growing regional market for distributed control systems. Rapid industrialization, infrastructure development, and expansion of power generation capacity drive demand across China, India, Japan, and Southeast Asia. Government initiatives promoting smart manufacturing, industrial digitization, renewable energy adoption, and emission reduction significantly support DCS deployment across the region.

North America

North America remains a mature yet innovation-driven DCS market. Strong adoption of advanced automation technologies, combined with regulatory emphasis on safety and efficiency, sustains market growth. Government programs encouraging digital manufacturing, energy efficiency, and modernization of industrial infrastructure further enhance DCS adoption.

Europe

Europe’s DCS market growth is shaped by stringent environmental regulations, energy transition goals, and widespread Industry 4.0 adoption. Government policies supporting decarbonization, renewable energy integration, and digital transformation across manufacturing and utilities continue to drive investments in advanced control systems.

Middle East & Africa

The Middle East & Africa region benefits from large-scale oil & gas projects and industrial diversification strategies. Governments are investing in smart industrial infrastructure to improve operational efficiency, safety, and sustainability, leading to increased adoption of modern DCS platforms.

Latin America

Latin America shows steady growth in the DCS market, driven by modernization of aging industrial facilities, expansion of energy infrastructure, and supportive government policies in power generation and utilities. Automation investments are increasingly viewed as essential for improving competitiveness and reliability across industries.

To Get Detailed Overview, Contact Us: https://www.cervicornconsulting.com/contact-us

Read Report: Distributed Cloud Market Revenue, Trends, and Strategic Insights by 2035