Carbon Fibers and Carbon Reinforced Plastic Market Size

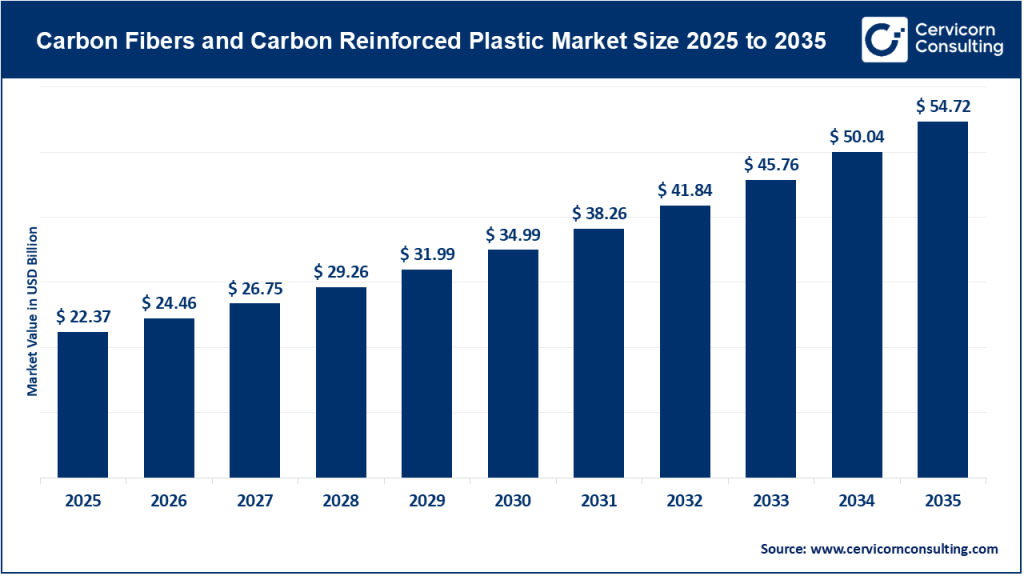

The global carbon fibers and carbon reinforced plastic market size was worth USD 22.37 billion in 2025 and is anticipated to expand to around USD 54.72 billion by 2035, registering a compound annual growth rate (CAGR) of 9.4% from 2026 to 2035.

What Is the Carbon Fibers and Carbon Reinforced Plastic Market?

The carbon fibers and carbon reinforced plastic (CFRP) market represents a critical segment of the advanced materials industry, focused on the production, processing, and application of high-performance composite materials. Carbon fiber is a material composed primarily of carbon atoms arranged in a crystalline structure, delivering exceptional tensile strength, stiffness, thermal stability, and corrosion resistance while remaining extremely lightweight. When these fibers are embedded into polymer matrices such as epoxy, polyester, or thermoplastic resins, they form carbon reinforced plastics, also referred to as carbon fiber reinforced polymers.

CFRPs combine the best characteristics of both components: the structural strength and rigidity of carbon fiber and the versatility and processability of plastics. These composites are increasingly replacing traditional materials such as steel, aluminum, and fiberglass in applications where weight reduction, mechanical performance, and durability are essential. The market spans a wide range of industries including aerospace, automotive, wind energy, construction, defense, marine, electronics, pressure vessels, and sporting goods, making it one of the most strategically important materials markets globally.

Why Is the Carbon Fibers and CFRP Market Important?

The importance of the carbon fibers and CFRP market lies in its ability to enable structural efficiency, energy savings, and next-generation engineering solutions across multiple industries. Lightweighting has become a global priority as manufacturers and governments seek to reduce fuel consumption, greenhouse gas emissions, and overall lifecycle costs of products. CFRPs provide superior strength-to-weight ratios compared to metals, allowing engineers to design lighter yet stronger components without compromising safety or durability.

In aerospace, carbon reinforced plastics significantly reduce aircraft weight, leading to lower fuel burn, extended range, and reduced maintenance requirements. In automotive manufacturing, CFRPs support the transition toward electric vehicles by offsetting the weight of batteries and improving vehicle range and performance. In renewable energy, particularly wind power, carbon fibers enable longer turbine blades that capture more energy while maintaining structural integrity. The market is also vital to defense modernization, hydrogen storage systems, advanced industrial equipment, and premium consumer products, positioning it as a cornerstone of modern industrial innovation.

Get a Free Sample: https://www.cervicornconsulting.com/sample/2870

Carbon Fibers and Carbon Reinforced Plastic Market Growth Factors

The growth of the carbon fibers and carbon reinforced plastic market is driven by a combination of regulatory, technological, industrial, and environmental factors, including rising demand for lightweight materials in aerospace and automotive sectors, increasingly stringent emission and fuel efficiency regulations worldwide, rapid expansion of renewable energy installations such as wind turbines, growing adoption of electric vehicles and advanced mobility platforms, increased defense and aerospace spending, and expanding applications in hydrogen storage, pressure vessels, and infrastructure. Additionally, advancements in manufacturing technologies such as automated fiber placement, resin transfer molding, and thermoplastic composites are improving production efficiency and scalability, while innovations in recycled carbon fiber and sustainable precursor materials are addressing cost and environmental concerns, collectively supporting strong long-term market growth.

Company Profiles: Key Market Leaders

Toray Industries, Inc.

Company: Toray Industries, Inc.

Specialization: PAN-based carbon fibers, prepregs, aerospace and industrial composite materials

Key Focus Areas: Aerospace structures, automotive lightweighting, wind energy, industrial applications

Notable Features: Vertically integrated supply chain, extensive R&D capabilities, long-term partnerships with global aerospace OEMs

2024 Revenue: Carbon fiber and composites segment revenues estimated in the multi-billion-dollar range

Market Share: Approximately 18–23% of the global carbon fiber market

Global Presence: Manufacturing and R&D operations across Japan, North America, Europe, and Asia-Pacific

Toray Industries is widely recognized as the global leader in carbon fiber production, with a strong emphasis on high-performance aerospace-grade materials and advanced composite systems. Its dominance is reinforced by long-term supply agreements with major aircraft manufacturers and ongoing investments in capacity expansion.

Hexcel Corporation

Company: Hexcel Corporation

Specialization: Carbon fibers, prepregs, woven fabrics, composite structural materials

Key Focus Areas: Aerospace, defense, automotive composites, wind energy components

Notable Features: Strong prepreg technology portfolio, proprietary fiber brands, automated manufacturing solutions

2024 Revenue: Carbon fiber and composites revenues in the high hundreds of millions to low billions USD

Market Share: Among the top five global carbon fiber and CFRP suppliers

Global Presence: Operations across North America, Europe, Asia, and the Middle East

Hexcel plays a crucial role in supplying advanced composite materials for commercial and military aircraft, as well as next-generation wind turbine blades and high-performance automotive components.

Mitsubishi Chemical Corporation

Company: Mitsubishi Chemical Corporation

Specialization: Carbon fibers, spread-tow fabrics, thermoplastic composite solutions

Key Focus Areas: Automotive components, industrial applications, sporting goods

Notable Features: Strong emphasis on thermoplastic composites, advanced fiber processing technologies

2024 Revenue: Carbon fiber segment revenues estimated in the mid-hundreds of millions USD

Market Share: Significant contributor to the Asia-Pacific carbon fiber market

Global Presence: Manufacturing and sales operations in Japan, Europe, China, and Southeast Asia

Mitsubishi Chemical’s strategic focus on thermoplastic CFRPs positions the company to benefit from high-volume automotive production and improved recyclability trends.

Teijin Limited

Company: Teijin Limited

Specialization: PAN-based carbon fibers, recycled carbon fiber products, advanced composite solutions

Key Focus Areas: Automotive electrification, aerospace, defense, industrial composites

Notable Features: High-strength fiber innovations, recycled carbon fiber technologies, lightweight automotive platforms

2024 Revenue: Carbon fiber and composites revenues in the high hundreds of millions USD

Market Share: Strong position in automotive and industrial composites

Global Presence: Japan, Europe, North America, and expanding Asia-Pacific footprint

Teijin is known for its focus on sustainability, lightweight mobility solutions, and integration of recycled carbon fibers into commercial applications.

SGL Carbon

Company: SGL Carbon SE

Specialization: Carbon fibers, continuous fibers, composite solutions

Key Focus Areas: Automotive structures, wind energy, industrial and infrastructure applications

Notable Features: Advanced continuous fiber technologies, sustainability-driven manufacturing, recycling initiatives

2024 Revenue: Carbon fiber and composites revenues in the mid-hundreds of millions USD

Market Share: Strong presence in Europe with growing global influence

Global Presence: Manufacturing facilities across Europe, North America, and Asia

SGL Carbon’s expertise in industrial-scale composite solutions and focus on circular economy practices strengthen its position in future-oriented applications.

Leading Trends and Their Impact on the Market

One of the most influential trends shaping the carbon fibers and CFRP market is the global shift toward lightweighting across transportation sectors. Automotive manufacturers increasingly adopt CFRPs to offset battery weight in electric vehicles, improve crash performance, and meet emission regulations. Aerospace manufacturers continue to increase composite content in aircraft structures to improve fuel efficiency and reduce lifecycle costs.

Another major trend is the rapid expansion of renewable energy infrastructure. Wind turbine manufacturers rely heavily on carbon fibers to produce longer, lighter, and stronger blades, enabling higher energy output and improved operational efficiency. Sustainability is also emerging as a defining trend, with increased focus on recycled carbon fibers, bio-based precursors, and energy-efficient manufacturing processes. Additionally, automation and digital manufacturing technologies are improving production consistency, reducing waste, and lowering costs, making CFRPs more accessible to high-volume applications.

Successful Examples of Carbon Fibers and CFRP Market Adoption Worldwide

In the aerospace industry, modern commercial aircraft platforms extensively use carbon reinforced plastics in fuselage sections, wings, and tail structures, resulting in significant reductions in fuel consumption and maintenance requirements. These aircraft demonstrate the long-term economic and environmental benefits of composite-intensive designs.

In the renewable energy sector, offshore and onshore wind turbines utilize carbon fiber reinforced blades exceeding 100 meters in length, enabling higher energy capture and improved reliability under extreme environmental conditions. These applications have become benchmarks for large-scale CFRP utilization.

The automotive industry has successfully integrated CFRPs into premium and performance vehicles, electric vehicle platforms, and structural safety components. In addition, hydrogen storage systems rely on CFRP pressure vessels to safely contain high-pressure hydrogen while maintaining low system weight, supporting the growth of hydrogen mobility ecosystems.

Beyond heavy industry, carbon reinforced plastics are widely used in sports equipment, bicycles, consumer electronics, and industrial robotics, where performance, durability, and design flexibility are critical.

Global Regional Analysis Including Government Initiatives and Policies

Asia-Pacific

Asia-Pacific represents the largest and fastest-growing regional market for carbon fibers and CFRPs, driven by strong industrial manufacturing bases, expanding aerospace and automotive sectors, and large-scale renewable energy deployment. China leads regional demand through electric vehicle production, wind energy installations, and domestic aerospace programs. Japan remains a global technology leader in carbon fiber innovation, while South Korea and India are emerging as important markets supported by industrial modernization initiatives.

Government policies in the region emphasize advanced materials development, domestic manufacturing capabilities, and clean energy adoption, all of which support sustained market growth.

North America

North America is a mature and technologically advanced market, characterized by strong demand from aerospace, defense, automotive, and clean energy sectors. The United States plays a central role due to its aerospace manufacturing base, defense spending, and research investments in advanced composites. Government initiatives supporting clean transportation, energy efficiency, and domestic manufacturing have accelerated CFRP adoption.

Europe

Europe’s carbon fiber and CFRP market is driven by stringent emission regulations, automotive electrification, and strong sustainability mandates. European governments actively promote lightweight materials to meet climate targets and support a circular economy. The region also benefits from advanced research ecosystems and strong collaboration between industry, academia, and policymakers.

Middle East, Africa, and Latin America

These regions represent emerging markets for carbon fibers and CFRPs, with growing adoption in aerospace supply chains, renewable energy projects, and infrastructure development. Governments are increasingly investing in industrial diversification, advanced manufacturing, and clean energy, creating long-term growth opportunities despite relatively smaller current market shares.

To Get Detailed Overview, Contact Us: https://www.cervicornconsulting.com/contact-us

Read Report: AI in Drones Market Revenue, Trends, and Strategic Insights by 2035